Neuroprosthetics inspire both amazement and fear concerning future possibilities more than any other area of AI development. There are some people who imagine a post-apocalyptic future when the talk of brain-computer interfaces (BCIs) surface: futures in which life has imitated art, and the portents of Science-Fiction films such as i-Robot and Terminator have been catastrophically realized.

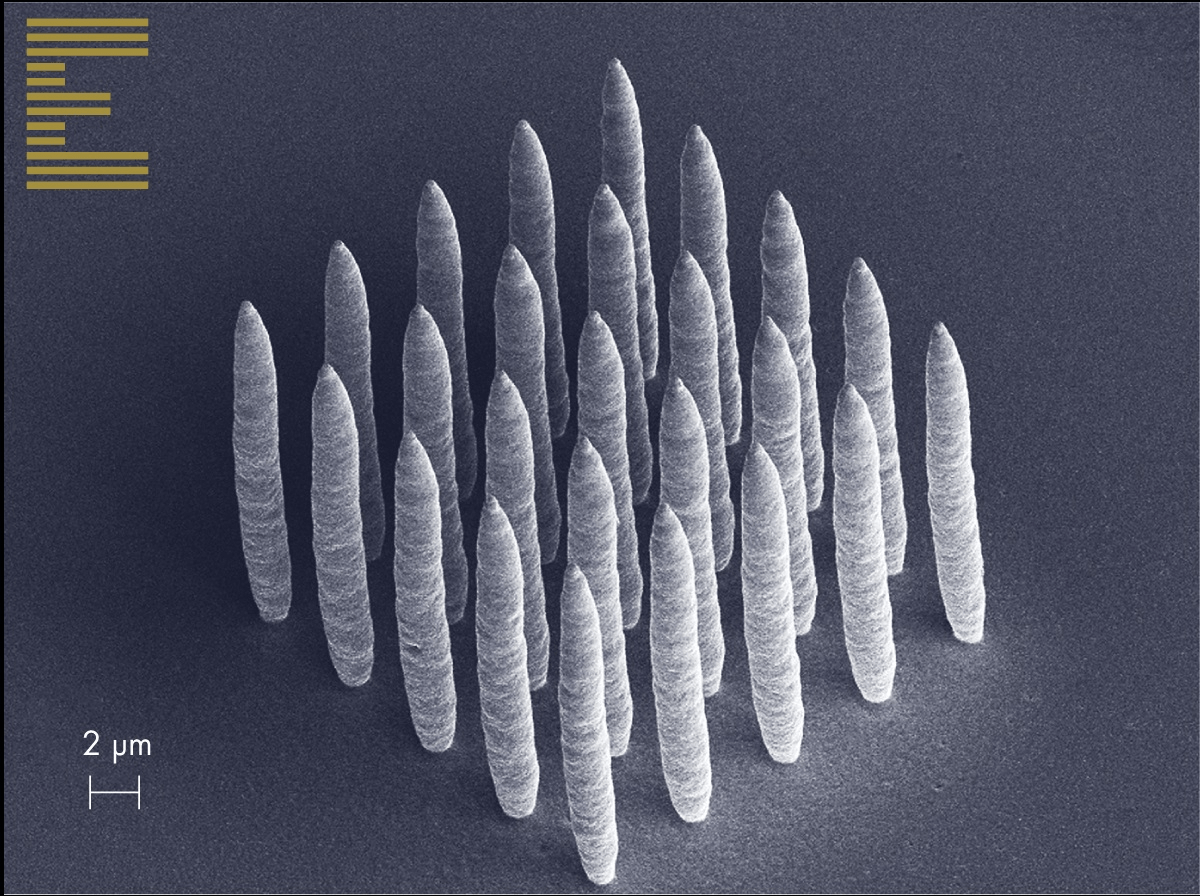

Copper micropillar array 3D printed on PEDOT:PSS. Image Credit: Exaddon

Even in a benign AI scenario, we will be left behind.

Elon Musk

However, researchers at any company or institution involved in BCIs/BMIs are happy to divulge details of an altogether different reality - one opposed to the dystopian cyborg future that is so often depicted by Hollywood.

Simply defined as the pairing of neuroscience with biomedical engineering, neuroprosthetics involves the use of external computing power to either replace or assist human functionality. Whilst neural control of robotic limbs has existed since 2008, new developments, with the advanced amalgamation of human-AI components, have recently come into being.

Active Companies

For companies such as Musk's Neuralink, the emphasis is firmly on ensuring the altruistic use of science. Like Paradromics, Columbia University and others, Neuralink are dedicating their resources and ambition to enhancing the lives of people suffering from extremely debilitating conditions such as Alzheimer’s and Parkinson’s disease, which are caused by the deterioration of neural pathways.

These BCI applications are utilizing artificial computing systems and power to offset the damaged nerve networks and brain functionalities in the patients: very different from Hollywood's images of computers controlling the human race.

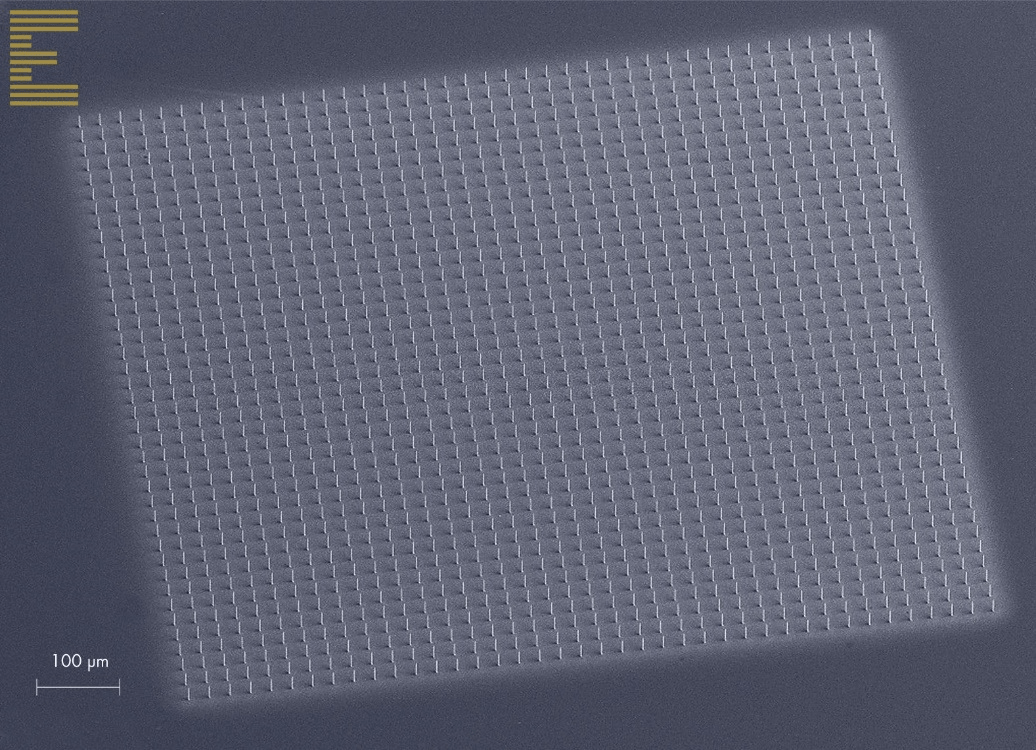

Object uniformity and repeatability: 1600 pillars printed on a 1 mm x 1 mm grid. Each pillar is ~1.6 µm Ø. Image Credit: Exaddon

Applications

These technologies are designed to perceive and perform functions that are no longer possible by the human body. This is achieved by placing an electrode sensor on the brain which is subsequently connected to external computing systems. From Columbia University’s Zuckerman Institute granting aphasic individuals with the power of speech, through to preventing seizures in patients with drug-resistant epilepsy [1] these applications are ground-breaking.

While the reality of having electrodes implanted into the brain is a justifiable concern, the possibilities which these devices permit for patients cannot be overemphasized. Enabling a quadriplegic individual to walk again by means of a thought-controlled exoskeleton is the granting of freedom that is incomprehensible to most able-bodied people. Similarly, giving back the power of speech to those with aphasia is an astonishing gift from an area of science that is still very much in its infancy. Some of the brightest minds on the planet are devoting themselves to advancing this profound and novel area of science, and what the future may hold is very incredibly exciting.

Inherent Technical Difficulties

However, these modern-day miracles are not simply a plug-and-play solution. This technology is necessarily highly-invasive because of the requirement of an implanted device – an exceptionally complex task.

Typically termed electrocorticography (ECoG), these implants/devices, which rest directly on the surface of the brain, provide much higher fidelity information than externally located electrodes. Yet, in terms of attachment, the implants also introduce much greater complexities. One of the essential requirements is the necessity for bio-compatible microscopic electrodes capable of conducting electrical signals from the brain, which are tiny enough to be left in-situ indefinitely. Defined as “µECoG”, the use of microscopic electrodes is a recent revolution that is fast gathering momentum.

Shortcomings of Existing Technology

Perhaps the major shortcoming concerning today’s implantable technology is the “mechanical mismatch between conventional rigid electronic materials and the dynamic, soft, and curvilinear human body” [2].

There are genuine concerns about long-term durability and comfort due to the inflexible nature of typical substrates. This is in conjunction with the necessity that any materials used possess high fidelity signal conductivity which in non-metals has demonstrated real issues.

Current approaches largely offer gold or platinum electrodes, on a range of substrate options, such as platinum, gold, iridium, polyimide, and others.

Utilizing flexible substrates comprising of arrays of micropillars have been explored as viable solutions, such as by Malliaras et al, [3] who fabricated PEDOT:PSS microarrays containing electrodes covering an area of 10 × 10 µm2, with a center to center distance of 60 µm. Since their study, PEDOT has been widely examined as a material with great promise in light of its combination of both good conductivity and flexibility.

Possibilities with Exaddon's µAM Technology

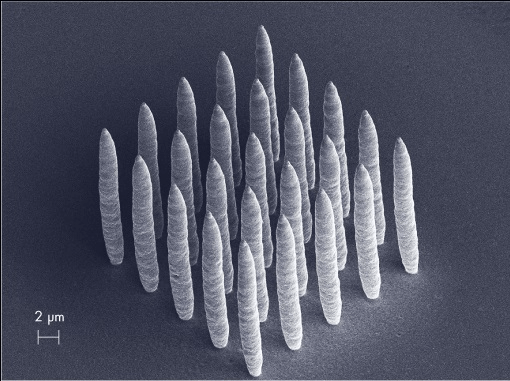

Image Credit: Exaddon

Exaddon’s novel µAM technology enables the printing of micropillars in pure metal with high conductivity. With diameters under 1 µm made possible, the CERES µAM print system is appropriate for printing the microscale metal structures essential for mechanically stable, conductive electrodes. The nanometer resolution of Exaddon’s system produces exceptional precision to the smallest metal production capabilities that are possible in 3D.

Illustrated above is a microneedle array printed on PEDOT:PSS as an exhibit of a workable solution and application of Exaddon’s CERES print technology to the rising field of neuroprosthetics.

References

[1] https://www.ncbi.nlm.nih.gov/pmc/articles/PMC6914250/

[2] Mehrali M, Bagherifard S, Akbari M, et al. Blending Electronics with the Human Body: A Pathway toward a Cybernetic Future. Adv Sci (Weinh). 2018;5(10):1700931. Published 2018 Aug 1. doi:10.1002/advs.201700931

[3] Khodagholy D., Doublet T., Gurfinkel M., Quilichini P., Ismailova E., Leleux P., Herve T., Sanaur S., Bernard C., Malliaras G. G., Adv. Mater. 2011, 23, H268.

This information has been sourced, reviewed, and adapted from materials provided by Exaddon.

For more information on this source, please visit Exaddon.

https://news.google.com/__i/rss/rd/articles/CBMigAFodHRwczovL3d3dy5uZXdzLW1lZGljYWwubmV0L25ld3MvMjAyMDEwMjkvTmV1cm9wcm9zdGhldGljcy1hbmQtQWRkaXRpdmUtTWljcm9tYW51ZmFjdHVyaW5nLWUyODA5My1FbmFibGluZy1hLUN5Ym9yZy1GdXR1cmUuYXNweNIBhAFodHRwczovL3d3dy5uZXdzLW1lZGljYWwubmV0L2FtcC9uZXdzLzIwMjAxMDI5L05ldXJvcHJvc3RoZXRpY3MtYW5kLUFkZGl0aXZlLU1pY3JvbWFudWZhY3R1cmluZy1lMjgwOTMtRW5hYmxpbmctYS1DeWJvcmctRnV0dXJlLmFzcHg?oc=5

2020-10-29 14:18:00Z

CAIiEIHv77OrPK64HY8Fob7735EqMwgEKioIACIQZdRflS9INK7zM5FkBi3R3CoUCAoiEGXUX5UvSDSu8zORZAYt0dwwr47MBg

Bagikan Berita Ini

0 Response to "Neuroprosthetics and Additive Micromanufacturing – Enabling a Cyborg Future? - News-Medical.Net"

Post a Comment